Propelling the World Forward

Sean Hilbert of Cobra AERO and Cobra MOTO

As president of Cobra AERO and its sister company Cobra MOTO, Sean Hilbert is contributing to the state’s mobility and aerospace industries and championing Michigan’s leadership in defense

Sean Hilbert was born and raised in Michigan, but just barely. He was born shortly after his parents moved from Northern California to East Lansing so that his dad could finish his engineering degree at Michigan State University (MSU). Sean’s dad was offered a job to run the engineering part of the National Superconducting Cyclotron Facility (succeeded by the Facility for Rare Isotope Beams), so Sean spent much of his upbringing in the eclectic mix of a college town.

Sean attended MSU for undergrad and grad school before working for Ford Motor Company in the powertrain research labs. He then attended MIT through the Leaders for Manufacturing program, a partnership between MIT and leading manufacturers including Ford to help the United States recapture world leadership in manufacturing.

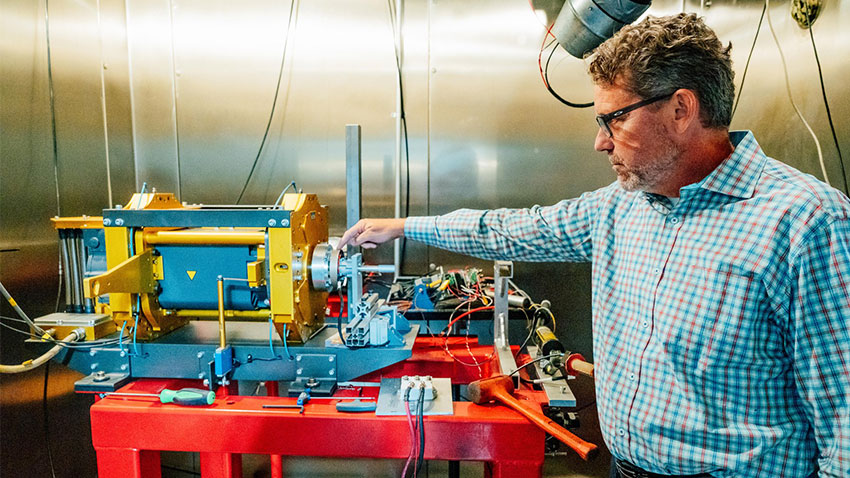

Sean is passionate about world leadership, as seen in his career path that led to the helm of Cobra AERO and its sister company, Cobra MOTO, starting in 2003. Based in Hillsdale, Cobra AERO is a precision manufacturer that makes advanced engine parts and propulsion systems for commercial and military drone vehicles. Its strong reputation in the U.S. and worldwide is built on excellence in engineering, innovative design, and cutting-edge techniques like additive manufacturing and CNC machining.

Cobra AERO’s international success has been driven by active engagement with the Michigan Economic Development Corporation (MEDC) International Trade program. With support through the Michigan State Trade Expansion Program and participation in the Michigan Pavilion at major global exhibitions such as Eurosatory and IDEX, Cobra AERO has effectively expanded its global reach. At IDEX, one of the world’s largest defense exhibitions, their leadership participated in a governor-led video interview, placing Michigan's manufacturing strength on an international stage. The company has also leveraged MEDC's foreign office services, including customized international market research, to enter new markets and grow their customer base.

At the core of Cobra AERO’s operations is a deep commitment to their Michigan roots. Many components in their supply chain are sourced from Michigan-based companies, reinforcing their dedication to the highest standards of quality. Sean shares this dedication and commitment, as he continues to champion Michigan as the best place to build things and build a future.

How did you come to work for the Cobra family of companies?

Coming out of my experience at MIT, I had a couple of close associates – good friends, actually – and we put a business plan together to change power sports. In the late 90s, one of the most interesting things that came out of the early internet was the ability to order a computer from Dell and have it a week later configured exactly to how you wanted it. That was an epiphany for me; I thought, ‘Wow, we could do that in so many other areas, including power sports.’ We shopped our business plan to the capital markets and found a private equity firm that really liked the idea and liked us. They said, ‘We're never going to invest in a startup, so go find a company to buy.’ There was a small startup out of eastern Ohio called Cobra Motorcycle Manufacturing. The owner really found a unique spot in the motorcycle market that hadn't been addressed. We looked at that and thought it was a good platform for us to start from. He was ready to sell, and we were ready to buy.

Eighteen months later, we were running this company that we had no idea how to run at the time. When I look back, I'm glad I was naive, because I wouldn't have made the same decisions otherwise. We grew that company dramatically for about a decade. Then the economic crisis hit in 2008, and the motorcycle market went off the cliff, literally. Our corner of the market was down by close to 80%, but we held on.

What led to the establishment of Cobra AERO?

By 2012, we sat down for some strategic conversations to look at which adjacent markets we should be pursuing that could be on a different economic cycle than very expensive consumer products. The Cobra MOTO market is high-end competition youth motorcycles, and so $6,000 toys for your eight-year-old don't go over well in a tough economic climate. We needed to look at something else that utilized our capabilities.

I had some friends in the Brighton area helping out some companies that were trying to fly autonomous aircraft. That market was in its fledgling stages, and I took a trip out to Insitu, a company on the West Coast; they’re a Boeing company that makes drone aircraft, mostly for the military. Their chief technology officer sat me down in front of their small aircraft, used for ISR – Intelligence, Surveillance and Reconnaissance. It’s basically a complex camera system that flies around in the air looking at things on the ground. He said, ‘I've got a $250,000 camera on that end of the plane, and I've got a $300 piece of crap engine that I could buy at a hobby shop on this end. I'm losing a million dollars in cameras a week because of engine failures. What can you do for me?’

We thought long and hard. We had an automotive background that enabled a manufacturing and quality mindset and a power sports background that was all about performance. Could we somehow glue those two things together and make the best UAS [Unmanned Aircraft System] on an autonomous small vehicle? Could we make the best small propulsion systems in the world?

That was the beginning of Cobra AERO.

What is innovative about Cobra AERO’s technology?

It's all about hybridization: propellers that are driven electrically, and a hybrid power plant in the belly of the aircraft. It makes electricity so it can stay in the air for long periods of time – sometimes for 15 or 20 hours. You can't do that on a battery alone. You have to charge those batteries while you're in the air, and so that's Cobra AERO. In the beginning, we spent five or six years in ‘stealth mode,’ but we didn't have products yet. We were developing, designing and integrating with different customer needs to figure out exactly what this business was going to look like. Fast forward to today, and we've got customers all over the world: Portugal, Abu Dhabi, Ukraine, South Africa, Australia, Canada, the U.S. and more. We are a world leader in the propulsion market for small autonomous vehicles.

How did you utilize MEDC support for Cobra AERO’s growth?

On the technology side of things, a high-performance propulsion system on a motorcycle and a high-performance propulsion system for an aircraft are somewhat similar – the scales are similar, the power output is similar and the technology that goes into them is similar. But the markets couldn't be further apart. One is an aspirational market that has a lot of flash and marketing, and the other market we were still trying to figure out.

Thankfully, we had a couple folks from the MEDC early on who recognized that we existed and came knocking on the door. I had no idea what I was doing, and I would take any advice I could get. We learned there are resources at the state to help you do things that you might not even know you had to do.

We learned about the MI-STEP grant program; at first, we used MI-STEP as trade show assistance. We went to trade shows in France, Germany and Abu Dhabi, and it was great. We have a very unique product and finding that needle in the haystack is tough. Understanding the marketplaces for unmanned aircraft is tough. The MEDC helped us with trade studies from countries like Turkey. The MEDC Trade team would say, ‘Here are the manufacturers that are producing aircraft in Turkey. Here are the people you might want to contact when you're at the show. In fact, we will have services at the show that help recruit those folks to you and help coordinate that sales effort.’ That's a big piece of the puzzle that's really helped us out.

Then I learned we could also use that assistance to help make specific sales calls with customers that are overseas, and to figure out what compliance is necessary to sell an aerospace product into a foreign country. I don't know how we'd have done it, honestly, without the kind of expertise that exists from the state.

Why is it important to keep the supply chain in Michigan and contribute to the state’s manufacturing legacy?

There are aspects of our supply chain that are global, but we've spent the last 20 years pulling things back to the U.S., mostly back to Michigan, and a lot back internally. Our mission is to keep our supply chain tight, to do things creatively from a tooling and a process standpoint, so that our costs can become really close to what you can find in Asia. We challenged ourselves, and we challenged our local supply base to figure it out. Michigan is an awesome place to make things, especially when you consider the built-in level of expertise that's here, and the fact that we have more engineers per capita than any place on the planet. It's just a great place to do business, and we're happy to be here.

How do you enjoy Michigan’s splendors outside of work?

We're huge outdoor folks. We love lake life. I love mountain biking, motorcycling and skiing. There's not a better place anywhere to have that variety of things across a variety of seasons. Michigan doesn't get the credit that it deserves when you can say, ‘You know what? I'm going to go mountain biking in the wintertime, or go skiing, or switch it up every few months and do something different and enjoy the new season.’

We’ve raised our kids here; they are all Spartans, too. One of my biggest goals is to make sure that they have a future in Michigan, and that Michigan is a vibrant place where young folks just want to thrive. That's my mission right now.

Where do you see your contributions to Michigan’s future in the defense and aerospace industry?

I am passionate about the state and bringing in dynamic companies in the defense and aerospace industry. If you look across the state, there are a few incredible, unique businesses in that sector. Most of the businesses in defense and aerospace are what I would term ‘traditional manufacturing’ – they do forgings, stampings, gears, machining or castings. What I hope we can bring back to the state over the next decade are ones that are up the value chain, so to speak. Primes. Why don't we make aircraft in this state? Why aren't we doing things that are, in scale and scope and vision, much grander? And I think we can. I know we can. We've got the people, and we have the infrastructure. There's no reason why we shouldn't be aggressive as a state and get that kind of stuff here. If there's anything I can do to help with that kind of mission, I will do it.

I'm really happy that the [Office of Defense and Aerospace Innovation] was created, and I hope we can do some true innovation through it. We're doing some cool research up at Michigan State right now that would change the way small vehicles are propulsed, with 40% more range. That's the kind of innovation that is going to change our state, bring real wealth here and make a better place for all of us.