Wednesday, October 29, 2025

Amped Up: Michigan’s Tech Talent Pipeline

Michigan students from kindergarten through college are honing cutting-edge tech and semiconductor skills with support from the Michigan Economic Development Corporation, in partnership with Washtenaw Community College, Kettering University and Ford.

“What do you want to be when you grow up?” It’s a question that’s hard to answer well, but programs aimed at filling Michigan’s technical talent pipeline are making it a bit easier. Talent programs supported by the Michigan Economic Development Corporation (MEDC) offer opportunities for students to experiment with semiconductors, programming and engineering at an early age and later develop certifiable skills as they complete their education. The goal? To empower a steady stream of capable, informed professionals in essential industries.

Efforts in partnership with Washtenaw Community College, Kettering University, Ford and many others are engaging students from kindergarten through bachelor’s degrees.

Washtenaw Community College

On the outskirts of Ann Arbor, Washtenaw Community College (WCC) enrolls more than 20,000 students each year and offers over 130 programs, supported by comprehensive training partnerships and transfer agreements with many four-year institutions, including the neighboring University of Michigan and Eastern Michigan University. In partnership with the MEDC, it’s helping both middle school and college students explore semiconductors, batteries and programming.

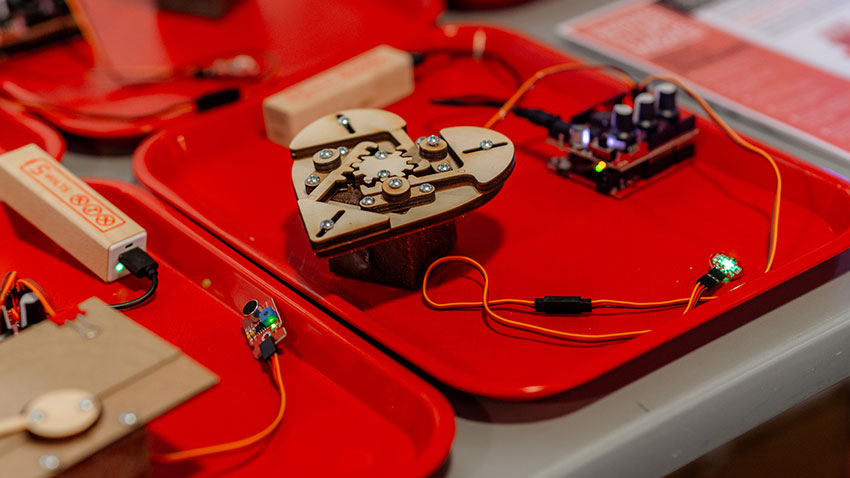

code:Possible shows middle school students how to hack it

In May 2025, more than 140 middle school students visited the WCC campus for “code:Possible – The Ultimate Middle School Hackathon.” Working in teams of 10, students used micro:bit STEM kits to tackle a real-world invention challenge designed by the SEMI Foundation and Make Stuff Move for improving sustainability at their schools, with support from University of Michigan Dearborn student mentors, Toyota volunteers and donated pizza from Domino’s. The kits were made available to provide workforce development for the semiconductor industry and build responsibility for sustainable technology use and development.

“We’re putting a lot of focus on the middle schoolers, because middle school is where they find the love for math, science, discovery and curiosity. We taught middle schoolers how to code, and we were able to give them their very own micro:bit, so they would be able to use it in school, take it home, share it with family and friends, and teach others,” said Bia Hamed, program manager for global education initiatives at the SEMI Foundation.

Example projects students can build include an alarm-equipped safe box and a stringless guitar made with aluminum foil contacts. “It starts them off with block coding, which is very simple. And from there, we show them the more difficult Python, so it’s a natural progression into an actual coding language,” said Hamed.

The previous summer, their teachers spent a week at WCC immersed in semiconductor education as part of the state’s commitment to making Michigan a leader in the semiconductor industry. Teachers were introduced to the SEMI Foundation’s “High Tech U” K12 curriculum on integrating semiconductor programming, and received micro:bit and CircuitScribe STEM kits for all of their students to support programming and emphasize hands-on STEM skills. Nearly 1,900 kits were distributed thanks in part to funding from the MEDC.

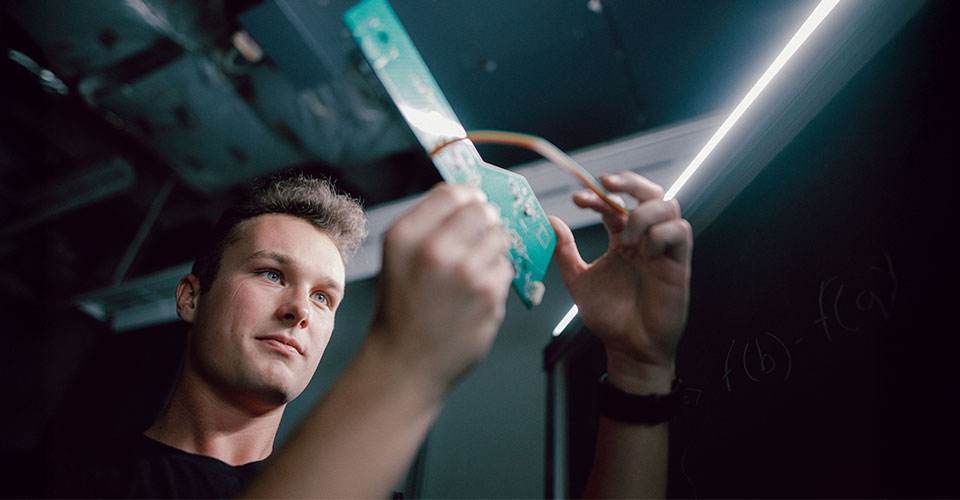

Associate degrees and certificates for semiconductor and battery mastery

WCC is also launching new academic pathways in EV battery manufacturing and semiconductor manufacturing, with support from MEDC Talent Solutions Strategic Investments in Education grant funding. These include an associate degree as well as an advanced certificate option, supported by three new courses: Hand Soldering Techniques (which prepares students for the industry recognized IPC J-STD-001 certification), Battery Manufacturing and Semiconductor Manufacturing. The associate degree pathway launched in Fall 2025, with the advanced certificate and new courses rolling out Winter 2026 and Fall 2026.

To bring these programs to life, WCC is investing in new equipment, upfitted lab spaces and faculty expertise. Faculty are working closely with industry partners and attending specialized training to ensure students graduate with the hands-on skills and certifications needed to succeed. These programs strengthen Michigan’s talent pipeline in two industries critical to the state’s future: EV battery and semiconductor manufacturing.

“The WCC Advanced Manufacturing Program is greatly enhanced by the planned addition of new programs such as semiconductor manufacturing, a simulated clean room, as well as twenty new training benches recently designed, assembled, and commissioned in our Programmable Logic Controllers (PLC) lab,” said William Sturm, professional faculty in advanced manufacturing at WCC. “These programs will offer our students valuable opportunities to learn and gain experience.”

Kettering University

One of Michigan’s most unique institutions of higher education is Kettering University. An engineering school founded in 1919 as “General Motors Institute” to serve the budding automotive industry, Kettering has a unique 50% workplace/50% classroom model. A commitment to “hands-on work” is enshrined in its Co-op program, considered the most robust in the country. Kettering students begin Co-oping with employers early in their first year and spend an equal amount of time over five years in the classroom and the workplace, graduating with a full two and a half years of meaningful job experience and significant earnings.

Now, Kettering is preparing its students for emerging industries, including semiconductors and hydrogen fuel technologies. Kettering announced a new accelerated semiconductor degree program, and has developed a number of new courses, including lab facilities and equipment, aided by $1.6 million in funding from the MEDC awarded in March 2025. The grant focused on four key areas of curriculum development and engagement, including semiconductors, hydrogen fuels, software engineering and pre-K-12 engagement. Kettering also supported 26 students as its inaugural class of Michigander Scholars recipients, the largest incoming class of any Michigan university, in April 2024. With more than 200 scholars, Kettering University ranks among the top institutions for inductees since joining the program.

Developing an accelerated semiconductor curriculum

Kettering faculty have been working on advanced coursework focused on semiconductor materials science, quantum physics and photonics, electronic design automation tools, semiconductor processing and device applications and computational modeling for semiconductor technology. In March 2025, Kettering announced an accelerated bachelor’s degree program in semiconductor materials and devices, and received formal approval in July from its accreditor HLC (Higher Learning Commission) to launch the new program. The first cohort of students will enroll in 2026.

Hydrogen fuels for cleaner air

Kettering has developed specialized training in hydrogen fuel technologies for both students and industry partners. As part of this effort, Kettering faculty created coursework connected to its Alternative Energy Concentration in Mechanical Engineering, which included hands-on work with fuel cell science. Professors and students partnered with the Flint Mass Transportation Authority to help design workforce development and public education programs on hydrogen bus operation, safety, and preventive maintenance. Together, these efforts linked Kettering’s academic expertise with Flint’s investment in clean public transit, ensuring that the launch of the hydrogen bus fleet was paired with a pipeline of talent and knowledge to sustain it.

Shaping software engineering for rapid change

Kettering faculty also developed new coursework in software engineering. This effort enhanced the university’s computer science offerings to augment its work in fields such as artificial intelligence, machine learning and large language models.

The new curriculum emphasizes both technical depth and human-centered design, giving students opportunities to build projects in areas like web systems, game design, UX and cybersecurity. By grounding these skills in real-world applications through Co-op placements, Kettering ensures students are prepared to solve industry challenges in Michigan’s mobility and intelligent manufacturing sectors, healthcare and beyond.

“Learn to Hack” over the summer

As part of its outreach mission, Kettering hosted two “Learn to Hack” week-long computer science camps in Summer 2025. These camps introduced students—many of them from Flint, Detroit and Women of Tomorrow partner schools—to topics such as game design, web development, machine learning, and large language models. Designed to be hands-on and collaborative, the camps emphasized project-based learning and group problem-solving, helping participants build confidence in coding and computational thinking while also experiencing the breadth of careers available in computer science.

Two cohorts of 30 middle and high school students participated through a residential or day camp option. Some students engaged in a session featuring Dr. Clarence Nixon, the founder and CEO at t.Lab, in which students designed an app prototype to help prepare students to assume leadership roles in the global marketplace, and visited either Ford Motor Company in Dearborn or Kunz, Leigh and Associates in the Lansing area.

Students described the camp as “one of the best experiences I've had all summer” and said they “would love to go to more of these camps in the future!”

Ford

Ford was one of the initial 15 employers to participate in the MEDC Talent Action Team when it launched in March 2023, and has been an active participant and strong supporter throughout the program. In 2026, 12 Ford Future Builders Labs — also known as Innovation Labs, Fabrication Labs or Digital Fabrication Labs — will be created in elementary schools, middle schools and high schools in Detroit, Marshall and surrounding Battle Creek schools in a first-of-its-kind collaboration with the MEDC’s Talent Action Team.

The initiative is projected to benefit nearly 7,300 kindergarten through 12th-grade students and 75 teachers in Michigan who will gain knowledge and skills needed in a variety of careers, including the skilled trades, advanced manufacturing and the auto industry.

Ford Future Builders Labs aim to help schools to modernize their classrooms with tools, such as 3D printers, laser cutters and CNC routers, that support learning in mechatronics, robotics and advanced manufacturing. Teachers will facilitate learning experiences that develop critical skills necessary for the 21st century, and students will engage in hands-on learning by designing, building and testing solutions to real-world challenges.

Learn more about Michigan’s award-winning talent solutions.