Success Story

Barron Industries

With MEDC support for a new advanced manufacturing center and international trade, the family-owned metal casting company is growing into a broader role at the heart of Michigan’s defense industry.

Metal casting is a core industrial technology, and the U.S. has seen significant consolidation and offshoring in recent decades, with the number of metal casting facilities in the U.S. falling from 6,150 in 1955 to 1,750 in 2024, according to Casting Source. In Michigan, Barron Industries has defied the trend and built a 100-year history in Oxford, in large part by refusing to stand still.

“One of the central challenges facing the consolidation of the casting industry is the reality that companies must either grow or be absorbed by larger organizations. While small, family-style operations are the foundation of our industry, remaining at that scale is increasingly difficult in today’s environment,” said CEO Bruce Barron. “Long-term stability now requires constant investment in new processes, advanced technologies and business development in order to support the workforce, infrastructure and overhead necessary to meet rising customer expectations.”

Through its collaboration with the Michigan Economic Development Corporation (MEDC), Barron Industries has secured critical resources to support this growth strategy. As a result, the company projects 20 percent annual growth through 2028, driven by new and expanded partnerships with aerospace and defense manufacturers, overseas sales and new and exotic capabilities.

More Space, More Tools, More Jobs

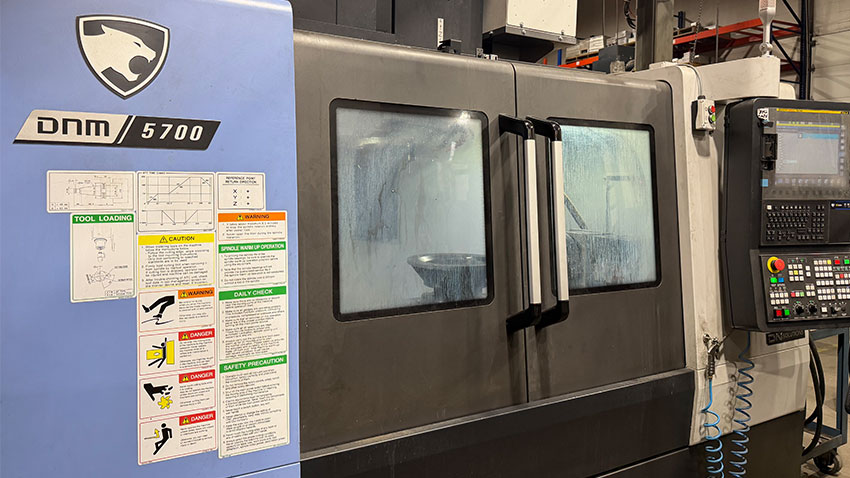

To help support this growth, the MEDC provided a performance-based grant of $900,000 through the Michigan Business Development Program (MBDP) toward a total $10 million investment in its new Aerospace and Defense Advanced Manufacturing Technical Center (ADAMTeC), adding 20,000 square feet of manufacturing space to accommodate new 3D printing and advanced machining equipment. The expansion will create about 50 high-paying skilled machine operator and programming positions averaging $30 per hour.

ADAMTeC is scheduled for completion in summer 2026 and will be fully operational by year-end, adding $25 million in new production capacity. The $10 million investment includes $4 million for building construction and $6 million in advanced manufacturing technology. More than $2 million in new equipment has already been purchased and is operating temporarily in existing facilities.

“In addition to 5-axis CNC machining equipment, we’re bringing in laser scanning equipment and 3D-printed ceramic shell equipment. We’ll make the precision investment casting process more competitive than any other 3D-printed metal process,” said Barron.

How to Thrive in a Shrinking Sector

Barron Industries is a complete turnkey manufacturer of precision-machined castings and assemblies. Its vertically integrated manufacturing process is unique for a metal casting company and significantly reduces cost and lead times. Its emphasis on quality is demonstrated by many certifications: NADCAP-certified for welding and non-destructive testing (including digital radiography and liquid penetrant testing), ISO 9001, AS9100, CMMC 2.0 and quality approvals from many major aerospace and defense OEMs including GE Aviation and Boeing.

The investment casting process is widely used across industries such as aerospace, automotive, medical and energy, where precision, durability and weight reduction are critical. Barron Industries' vertically integrated process offers significant design and material flexibility. For example, the company helped a defense customer reduce costs by more than 65 percent by converting a 12-part fabrication into a single-piece casting, which serves as both an engine mount and an alternator mount for a power pack used on a new generation armored personnel carrier.

The investment casting process is widely used across industries such as aerospace, automotive, medical and energy, where precision, durability and weight reduction are critical. Barron Industries' vertically integrated process offers significant design and material flexibility. For example, the company helped a defense customer reduce costs by more than 65 percent by converting a 12-part fabrication into a single-piece casting, which serves as both an engine mount and an alternator mount for a power pack used on a new generation armored personnel carrier.

Bringing Barron to the World

In recent years, Barron Industries has taken advantage of Michigan’s State Trade Expansion Program (STEP) to grow its oversea sales to more than a quarter of its total business.

Barron Industries first used the STEP grant program more than 15 years ago, beginning with a strategic trade mission to Israel aimed at expanding export markets for its defense-related products. The company continues to participate in major international trade shows in the United Kingdom, France, Canada and Germany, strengthening its brand across Europe and among key U.S. allies, with STEP support. Over this period, export sales have increased from less than 10 percent of total revenue to more than 25 percent, with international growth keeping pace with its overall annual expansion. The company is joining the MEDC trade mission to Eurosatory in June 2026.

“Through our participation in overseas defense and aerospace trade events, we have gained valuable insight into global market dynamics. Many international customers strongly favor their domestic supply base, which means U.S. suppliers must clearly differentiate themselves to compete effectively,” said Barron. “Barron’s competitive advantage lies in our vertical integration — our ability to deliver fully engineered, end-to-end subsystem solutions rather than simply supplying individual castings. If we were only offering a standalone casting, we would not be nearly as successful in these international markets.”

Building an Industry in Michigan

Southeastern Michigan — and the state of Michigan as a whole — has long been a strong manufacturing base supporting the defense and aerospace industries, anchored by a well-established defense corridor in the region. Barron Industries’ presence strengthens this ecosystem. “We support both original equipment manufacturers in Michigan, such as General Dynamics, Eaton Aerospace, BAE Systems and others, and also the major Tier 1 suppliers that serve these OEMs,” said Barron.

“As a Michigan-based precision casting and machining company holding AS9100, NADCAP, Boeing and GE certifications, Barron has enabled several of our customers to pursue new business opportunities that were previously out of reach,” he added. Many needed a qualified domestic source for key components: both machined precision castings and the fully engineered component subsystems required for complex applications, including HVAC systems, power plants, turrets and other advanced integrated systems. In many cases, this collaboration helped Barron’s suppliers and customers diversify into defense and aerospace, reducing their reliance on automotive and commercial trucking clients and strengthening the overall resilience of Michigan’s manufacturing economy.

The MEDC supports these efforts through the Office of Defense and Aerospace Innovation which fosters growth in the state’s defense and aerospace sectors. These industries contribute $30 billion in economic activity, more than 166,000 jobs and nearly 5,000 Michigan businesses serving the defense, defense aerospace and homeland security industries.

Barron also participates in the Michigan Maritime Manufacturing (M3) Initiative – a partnership between Michigan and the federal government aimed at bolstering workforce and supplier development. The M3 Initiative at Macomb Community College teaches critical skills for maritime construction, particularly in maritime welding and machining.

Stepping Up the Complexity Ladder

Looking beyond the planned opening of ADAMTeC, Barron Industries sees even more titanic opportunities ahead.

“There’s a great demand for titanium in the defense and aerospace industries, and Barron is focusing on ground-based defense or ground-based aerospace applications for titanium castings. There's a shortage of supply,” said Barron. “It is a more complex and capital-intensive venture to get into, but Barron is looking very seriously at adding capacity for titanium production. That will make it one of just a handful of companies in the United States that possess that capability.”