Belmont Engineered Plastics

Custom Injection Molding Business Thrives in Grand Rapids with Support from the Michigan Economic Development Corporation’s Capital Access Team

When Stephen King’s employer decided to offshore and shut down business in 2013, he readily stepped in to buy the 146,000 square foot manufacturing facility, which is now home to Belmont Engineered Plastics (BEP).

“Some of the employees had worked for the company for 40 years, and we were so thankful for the opportunity to purchase the building because we felt so passionately about the team,” said BEP Chief Financial Officer Mike DaMore. “We believe wholeheartedly in taking care of our employees. Making BEP a place employees love to work is going to result in our customers also loving working with us.”

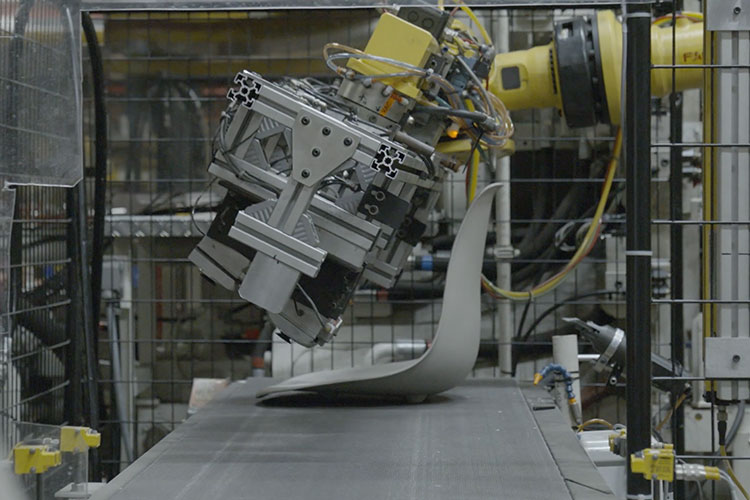

BEP manufactures injection molding, and thermoformed and assembled products to customers in Europe, Latin America and Asia. The company places an emphasis on sustainable production to ensure products meet quality standards while limiting environmental impact.

The last eight years of business have been a tough road to success for BEP, but the company received critical support from the Michigan Economic Development Corporation (MEDC) and its Capital Access Team along the way.

When the BEP team was in the process of launching their new business, they had no history working with a bank, which limited their options as it was difficult for a financial institution to measure risk. In 2013, BEP worked with MEDC to attain a $900K grant to continue their injection operations.

Six years later, in 2019, the Capital Access’ Collateral Support Program allowed BEP to obtain a working capital line of credit through First National Bank, providing the companythe funds necessary to purchase equipment and grow their team further.

“This would not have happened, as we rewind back to 2013, without support from the Grand Rapids community and organizations like the MEDC,” says Mike. “The MEDC was willing to invest in us because we were committed to growing in Michigan and maintaining local jobs.”

As a result of the partnership between BEP and the MEDC, the company now processes more than 200 shipments a month and its manufacturing facility has grown to include 40 injection molding presses, 12 assembly lines and three customization areas.

To learn more about the MEDC’s Capital Access Team and how they can help your business acquire funding, please visit https://www.michiganbusiness.org/pure-partnership/.